What is Pellet Binder?

A suitable pellet binder is not actually the name of a specific additive used in livestock and poultry feed mills, but the properties of the nutrients that make up the feed.

Starch and some other types of polysaccharides, soluble sugars, and proteins in the feed can have binder pellet properties.

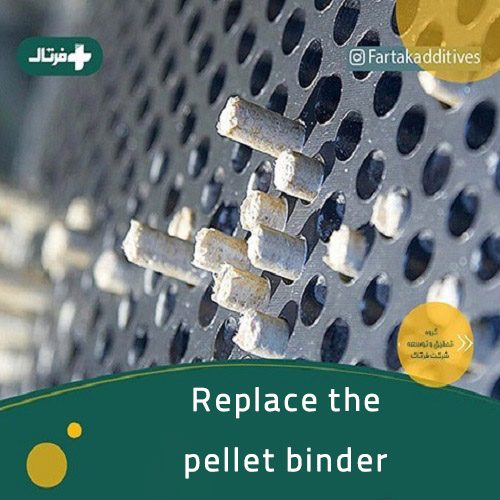

However, adding pellet binder to the pellet feed production formula is common in animal feed mills today due to the need to increase pellet consistency.

A pellet feed suitable for livestock, poultry, aquatic animals, etc. should have a strong structure to maintain its physical shape from production to consumption by the animal

Also, in some cases, it may be impossible to pellet the feed without a suitable pellet binder. Therefore, using a suitable pellet binder plays an important role in the success of the feed pelleting process.

What are the features of pellet binders?

Pellet binders have properties that help to put food particles together in the pellets. The most important of these properties are the ability to absorb water and create bonds between the particles that make up the feed.

In fact, pellet binders play their role in two stages of the pelleting process. First, when the mixed feed enters the condenser, they increase the feed moisture by absorbing the injected moisture in the form of steam.

This action is effective in the ductility of the feed mixture as it passes through the die.

The second stage is when the feed is compressed between the die and the roller in the pellet press machine or between the screw and the lattice plate in the extruder machines, which hold the pellet binder materials together like a strong cement of the feed particles.

That’s why barley and wheat feeds, which contain higher levels of NSP, form stronger pellets.

Re-evaluate your pellet binder

In our country, the first name that comes after the word pellet binder is bentonite. Bentonite is actually an aluminosilicate mineral that is mined.

Existence of many sources of bentonite in Iran has caused this mineral to become popular as the cheapest and most common binder pellet in animal feed production plants.

Bentonites in different types, processed or not, in different brands have been widely used in feed mills.

But it is time to answer this question; Is bentonite, in addition to being the cheapest, also the most suitable pellet binder for use in the feed industry?

To get closer to the answer to this question, it is necessary to address some of the effects of bentonite on the production and quality of pellet feed. You know that minerals increase the depreciation of the feed production process with their strength.

Bentonite with sedimentation in the die pores gradually causes the holes to close or so-called cape, which in the long run reduces the efficiency of the pelletizing process or unusable die and the need for repair.

Because the resistance created by them causes more pressure on the pellet press machine and in addition to increasing depreciation, energy consumption also increases.

Also, minerals are generally malignant and increasing them in food reduces palatability.

Bentonite can be effective in reducing the palatable taste of food because a relatively significant amount of it must be added to food to be effective. This also seems to be a limitation in foods such as poultry starters or super-productive animals that require high concentrations of energy, protein and other nutrients.

Cases of combining bentonite with micronutrients and reducing their absorption in the intestine have also been observed.

Bentonite replacement binder pellets

Starchs, especially corn starch, which has a higher proportion of branched polysaccharides called amylopectin than starch, have strong binding pellet properties.

Also gluten, which is composed of two parts, gliadin and glutenbone, and these two polypeptides form a strong network with cross-links. Gluten is actually rooted in the Latin word glu, meaning glue, and has long been used in the cooking of bread, pastries, biscuits, and other food industries.

Because heat treatment of gluten along with starch creates a strong compound.

Gums, natural and synthetic resins and other adhesive materials that are harmful to the animal or its consumer can also be other options for use as pellet binders.